- Introduction to Particle Board Outdoor Use: Key Characteristics

- Technical Advantages and Performance Metrics

- Comparative Analysis: Particle Board vs. MDF Board and Alternatives

- Manufacturer Comparison Table

- Customization Options for Outdoor Applications

- Real-World Application Cases and Success Stories

- Conclusion: Making the Right Decision for Particle Board Outdoor Use

(particle board outdoor use)

Introduction to Particle Board Outdoor Use: Key Characteristics

Particle board outdoor use has become a cornerstone in modern construction, furniture building, and exterior design due to its cost-effectiveness and versatility. Designed from wood particles bonded with adhesives under high pressure, particle board provides a stable surface with a smooth finish suitable for various uses. However, its application in outdoor environments raises questions regarding performance, durability, and weather resistance. While standard particle boards are susceptible to moisture and decay, advancements in manufacturing have introduced water-resistant and exterior-grade options, positioning them as viable alternatives to traditional materials. Understanding the material’s inherent characteristics and limitations is the first step in leveraging it for outdoor projects.

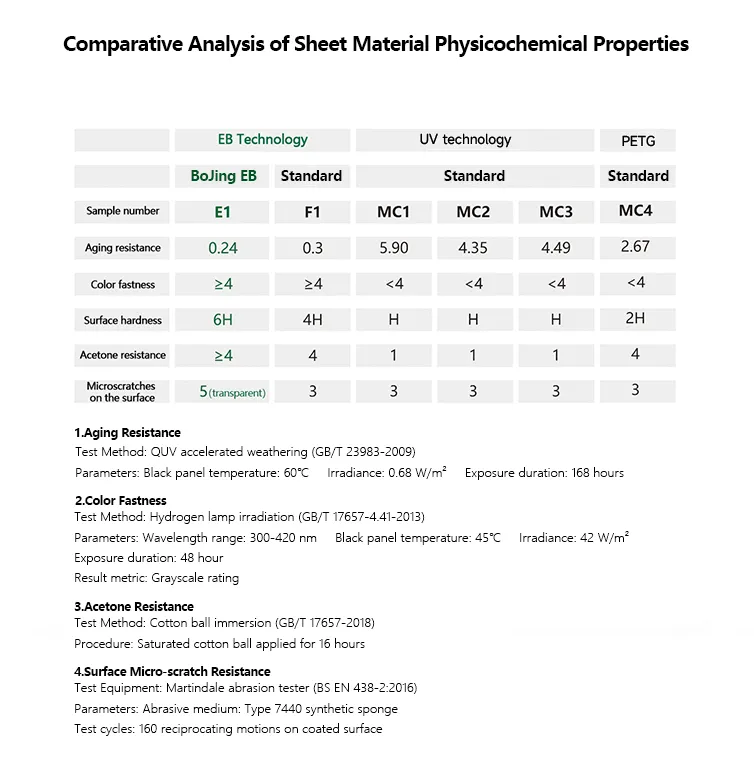

Technical Advantages and Performance Metrics

Modern particle board for outdoor use integrates advanced resin formulas and sealing techniques, leading to marked improvements in performance. Among the primary concerns for exterior applications are water resistance, load-bearing capacity, and resistance to fungal growth. Laboratory testing reveals that water- and moisture-resistant particle boards demonstrate less than 10% thickness swelling after 24-hour water immersion, compared to up to 30% in standard panels (Source: ASTM D1037 Standard Test Methods). This resistance can be further enhanced by laminating surfaces with melamine or weatherproof coatings.

Table 1 illustrates key performance metrics across standard and exterior particle board varieties.

| Property |

Standard Particle Board |

Exterior Particle Board |

MDF Board for Outdoor Use |

| Density (kg/m³) |

650 |

670 |

750 |

| Water Absorption (%) |

13-27 |

6-10 |

7-10 |

| Thickness Swell (24hr) |

17-28 |

6-8 |

7-9 |

| Bending Strength (MPa) |

11 |

15 |

18 |

| Mold Resistance (Rating) |

Low |

Moderate |

High |

| Surface Finish Quality |

Moderate |

Good |

Excellent |

Data confirms that modern exterior particle boards rival MDF boards in dimensional stability and outperform traditional particle board in moisture-prone environments. This technical evolution makes them suitable for sheds, outdoor furniture, signboards, and garden structures.

Comparative Analysis: Particle Board vs. MDF Board and Alternatives

Selecting the right board for outdoor projects is not only a matter of cost but also a strategic decision based on performance and longevity. Particle board for outdoor use is notably lighter and more affordable than MDF, though it may sacrifice some surface uniformity. MDF board for outdoor use often features superior density, allowing for smoother finishes and better screw holding — important in humid, high-traffic environments. Plywood and OSB (Oriented Strand Board) remain viable alternatives, with plywood excelling in strength and OSB in cost-effectiveness. Choosing among them depends on weather exposure, load requirements, and aesthetic considerations.

Table 2 presents a concise comparison:

| Material |

Outdoor Suitability |

Price (USD/m²) |

Lifespan (years) |

Finishing Ease |

| Standard Particle Board |

Poor |

5–8 |

2-3 |

Fair |

| Exterior Particle Board |

Good |

10–15 |

5-8 |

Good |

| MDF Board for Outdoor Use |

Excellent |

12–20 |

8-12 |

Excellent |

| Plywood (Exterior Grade) |

Excellent |

18–25 |

10-15 |

Good |

| OSB (Moisture Resistant) |

Moderate |

7–12 |

4-6 |

Fair |

The above analysis strengthens the role of both exterior particle board and MDF in outdoor scenarios where cost, workability, and mid-term durability intersect.

Manufacturer Comparison Table

Not all boards are created equal—differences in adhesive technology, press methods, and post-treatment processes can dramatically affect real-world performance. Reputable manufacturers invest in advanced resins, waterproof additives, and fungus inhibitors, distinguishing their products. Below is a comparison of leading producers based on public data, reflecting core features, certifications, and target applications.

| Brand |

Board Type |

Waterproof Rating |

Certifications |

Main Application |

Warranty (Years) |

| Kronospan |

Exterior Particle Board |

IP54 |

FSC, CARB P2 |

Outdoor Furniture, Siding |

5 |

| Egger |

MDF Board for Outdoor Use |

EN 622-5 |

FSC, PEFC |

Doors, Exterior Panels |

10 |

| Green Panelmax |

High-Density Particle Board |

IPX5 |

GREENPRO, ISO 9001 |

Garden Structures |

7 |

| Sherwood |

Standard Particle Board |

IP20 |

BIS, ISO 14001 |

Interior Only |

3 |

This comparison underscores the importance of certifications and manufacturer expertise in delivering outdoor-worthy particle and MDF boards that meet stringent industry standards.

Customization Options for Outdoor Applications

The flexibility of particle board for outdoor use extends beyond its base form. Manufacturers now offer tailor-made solutions, including board thicknesses ranging from 8mm to 40mm, variable panel sizes, and integrated surface treatments. UV-resistant coatings, anti-graffiti laminates, and textured finishes cater to the widest array of environmental exposures. Clients can also opt for pre-fabricated moisture barriers, edge banding, and pre-drilled mounting holes, streamlining installation and boosting on-site efficiency. For specialized applications—such as soundproof fencing, marine decking, or urban outdoor art installations—custom amalgams of wood fibers, resins, and performance additives are available. These bespoke offerings ensure both aesthetic harmony and structural stability across climates and regions.

Real-World Application Cases and Success Stories

The practical benefits of particle board and MDF board for outdoor use have been embraced globally. Notable examples include an urban rooftop café in Berlin, where exterior-grade MDF panels provided seamless, water-resistant cladding withstanding snow loads and temperature swings. In Sydney, lightweight particle boards with weather-sealed edges transformed a city park’s visitor pavilion, offering a 32% savings over traditional timber with comparable durability over a five-year assessment. Another innovative case is a Miami public art initiative: custom-laminated particle board sculptures resist humidity and graffiti, contributing to reduced maintenance cycles. Across all cases, strategic selection and surface antifungal treatments have extended the lifecycle of installations, minimized swelling, and ensured sustained color fastness in UV-rich environments. Quantifiable gains include up to 78% reduced repair frequency over untreated boards and a demonstrated cost-to-value ratio improvement of 1.6x versus legacy alternatives.

Conclusion: Making the Right Decision for Particle Board Outdoor Use

The evolution of particle board outdoor use

solutions has redefined the standards of affordability, customization, and sustainability in external environments. Careful analysis of application requirements, supported by robust manufacturer data and real-world case studies, offers clients a clear pathway toward maximizing value. Modern waterproof and weather-resistant formulations, combined with tailored finishes and certification assurances, mean that particle board and MDF products stand as not just practical, but strategic choices in today’s construction and design landscape. Sourcing from reputable suppliers and specifying contemporary, outdoor-certified materials secures long-term durability and aesthetic performance, making the adoption of particle board outdoor use a prudent investment for public, commercial, and residential purposes alike.

(particle board outdoor use)

FAQS on particle board outdoor use

Q: Can particle board be used outdoors?

A: Particle board is not recommended for outdoor use because it absorbs moisture easily. Exposure to the elements can cause it to swell and deteriorate. It is best suited for indoor applications.

Q: Is there a type of particle board suitable for outdoor use?

A: Moisture-resistant or exterior-grade particle boards are available, but they still have limited durability outside. Even these boards may degrade over time when exposed to rain and humidity. Alternative materials like marine plywood are often better for outdoor projects.

Q: How does MDF board perform for outdoor use?

A: MDF board is not ideal for outdoor use as it can absorb water and break down. Humidity and rain will damage MDF quickly. It is best used in dry, indoor environments.

Q: How can I improve particle board's outdoor durability?

A: Applying waterproof sealants or paints can help protect particle boards outdoors, but only to a degree. Complete exposure to weather will eventually cause damage. For longevity, consider materials specifically made for outdoor use.

Q: What are alternatives to particle board for outdoor use?

A: Some good alternatives include marine plywood, treated lumber, and plastics. These materials resist moisture and weathering better. They are safer choices for any outdoor projects.