- Introduction to fiber board for furniture

- Material properties and technical advantages

- Comparative analysis: furniture board vs. plywood cabinets

- Manufacturer landscape and industry leaders

- Customization options and versatility

- Application cases and practical implementation

- Conclusion: Why choose fiber board for furniture in the modern furnishing market

(fiber board for furniture)

Introduction to fiber board for furniture

The evolution of modern home and office furniture has brought renewed attention to engineered materials, particularly fiber board for furniture. Engineered to deliver efficiency, consistency, and reliability, fiber board has become a foundational component in numerous furnishing applications worldwide. It meets a growing demand for materials that harmonize sustainability, performance, and cost-effectiveness. Whether used in cabinetry, shelving, paneling, or custom furniture, fiber board distinguishes itself through a blend of technological advancement and user-centric traits that elevate both function and form in the furniture industry.

Material Properties and Technical Advantages

Fiber board, often referred to as MDF fiber board (Medium Density Fiberboard), is an engineered wood product crafted from wood fibers, wax, and resin—compressed and formed at high temperatures and pressures. The result is a dense, smooth, and highly uniform board with no distinctive wood grain, voids, or knots. The technical composition brings a range of advantages:

- Surface Smoothness: The absence of grain and consistency in texture make MDF an ideal substrate for veneering, painting, or laminating, enabling seamless finishes.

- Stability: Unlike solid wood, fiber board is less prone to warping, expansion, or contraction from temperature and humidity changes—critical attributes for furniture longevity.

- Machinability: The homogeneity of fiber board allows precise cutting, drilling, routing, and shaping, supporting intricate designs and efficient production processes.

- Environmental Credentials: Many manufacturers now utilize recycled wood fibers and formaldehyde-free resins in MDF, aligning with green building and indoor air quality standards.

In industry tests, modern MDF exhibits an average Modulus of Rupture (MOR) between 39 MPa and 45 MPa and a Modulus of Elasticity (MOE) ranging from 2550 MPa to 3300 MPa, confirming its suitability for a broad spectrum of furniture applications. Fire-rated and moisture-resistant grades further increase the material’s versatility, providing options for kitchens, bathrooms, and commercial interiors.

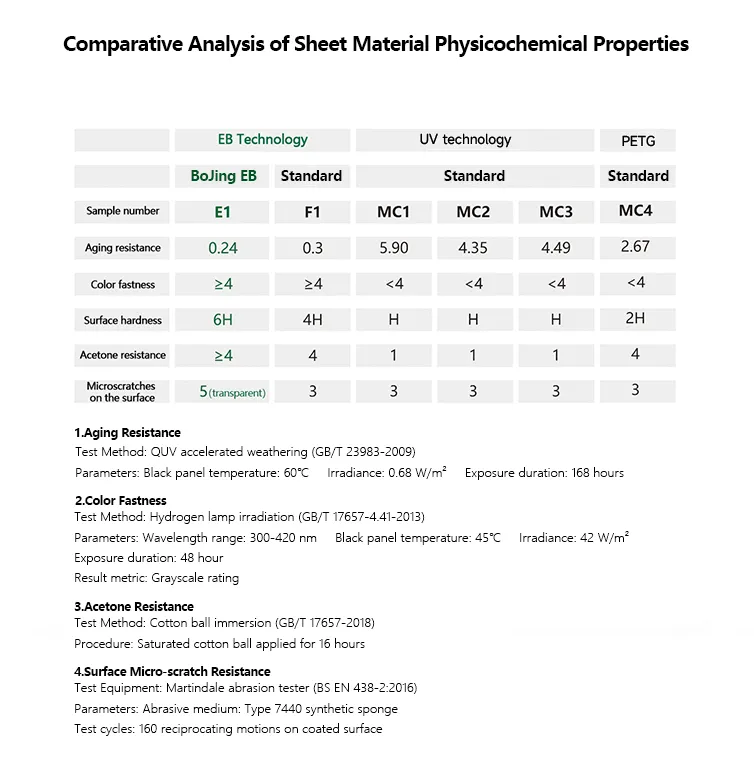

Comparative Analysis: Furniture Board vs. Plywood Cabinets

The debate between fiber board-based furniture components and plywood remains significant for buyers and designers. Each material carries distinct properties that affect appearance, structural performance, and overall cost. The comparison below offers a data-driven perspective:

| Attribute |

Fiber Board (MDF) |

Plywood |

| Density (kg/m³) |

600 – 850 |

400 – 700 |

| Surface Finish |

Exceptionally smooth; ideal for painting/veneering |

Visible grain, can splinter |

| Bending Strength (MOR, MPa) |

39 – 45 |

55 – 65 |

| Stability in Moisture |

Susceptible unless moisture-resistant grade |

Generally more stable |

| Workability |

Excellent; supports intricate milling |

Good, but can chip at edges |

| Environmental Impact |

Often uses recycled content |

Depends on veneer source |

| Cost (2023, USD/m² for 18mm board) |

$12 – $18 |

$18 – $28 |

| Application Examples |

Painted cabinets, doors, shelving, custom panels |

Structural cabinetry, load-bearing shelving |

The data highlights MDF’s competitive edge in surface quality, uniformity, and affordability, while plywood presents superior structural strength and moisture stability. The choice between furniture board vs plywood cabinets ultimately hinges on end-use requirements, desired aesthetics, and budget allocations.

Manufacturer Landscape and Industry Leaders

The global market for fiber board and furniture boards is highly competitive, featuring both multinational corporations and specialized local suppliers. Top international MDF producers like Kronospan, Egger Group, and Arauco collectively generate over 30 million cubic meters of fiber board annually—serving a diverse clientele that spans residential, commercial, and institutional sectors. Technical innovation also drives smaller, niche players to target custom markets, such as flame-retardant and high-density boards for specialty furniture and retail fixtures.

Manufacturing capabilities have benefited from automation, continuous presses, and eco-friendly resin technologies, with line speeds now exceeding 2,000 meters per day and recovery rates above 95% for raw fiber materials. Key factors differentiating suppliers include:

- Certifications: Leadership in environmental and quality credentials such as FSC®, ISO 9001, and CARB Phase II compliance.

- Continuous R&D: Investment in VOC reduction, fire and moisture retardancy, and increased product customization.

- Regional Reach: Ability to support global supply chains and localized inventories.

Selecting the right manufacturer is often a matter of balancing consistency, technical support, lead times, and alignment with project-specific requirements.

Customization Options and Versatility

Fiber board solutions are inherently versatile, supporting bespoke designs that meet individual, commercial, or architectural expectations. Customization spans multiple vectors:

- Thickness and Dimensions: Standard sheets are available from 3mm to 30mm thickness, with widths up to 2100mm and lengths exceeding 2800mm for large-format architectural components.

- Surface Options: A vast selection of veneers, laminates, high-gloss, matte, or textured finishes ensures seamless aesthetic integration.

- Technical Specifications: Moisture-resistant, fire-retardant, and formaldehyde-low or -free board grades cater to regulatory and environmental demands.

- CNC Machining: Advanced factory toolpaths facilitate intricate carvings, inlays, grooves, and edge profiles with micron-level accuracy.

- Color and Pattern Matching: Digital printing and UV-curing processes deliver infinite custom patterns, company logos, or interior themes efficiently.

Modern manufacturing partners offer end-to-end customization, integrating 3D design, rapid prototyping, and batch production to satisfy one-off design statements or high-volume commercial rollouts. This flexibility enables furniture designers and architects to realize bold concepts and embrace functional innovation.

Application Cases and Practical Implementation

Fiber board’s track record spans a spectrum of real-world environments. Consider these case applications:

- Educational Spaces: Schools across Germany and Scandinavia, aiming for durability and hygiene, have standardized laminated MDF panels for desks, wall partitions, and acoustic panels, reducing maintenance costs by 30% and repair frequency by 40% within five years.

- Retail Interiors: Global retail chains (e.g., IKEA, Target) opt for fiber board with digitally printed surfaces for shelving and bespoke fixtures, streamlining store rollouts and ensuring consistent branding across 1,000+ stores worldwide.

- Residential Cabinetry: In the United States, fiber board-based kitchen cabinets account for 60% of all semi-custom and stock units sold—a $5 billion annual market segment. Homeowners cite finish quality, ease of cleaning, and a 20% average cost saving over plywood alternatives as top benefits.

- Hospitality Sector: Hotels and serviced apartments utilize moisture-resistant MDF in bathroom vanities and wall paneling, extending replacement cycles by two years on average compared to traditional particle board.

- Corporate Offices: Fiber board solutions support modular workstation construction, allowing for reconfiguration and integrated data routing, facilitating agile work environments.

These proven use cases underscore the reliability and broad appeal of fiber board in meeting diverse technical, functional, and aesthetic requirements.

Conclusion: Why choose fiber board for furniture in the modern furnishing market

As the furniture industry embraces cutting-edge design thinking and stringent sustainability objectives, fiber board for furniture emerges as a vital material choice. Its harmony of surface perfection, adaptability, and competitive pricing supports the creation of both trend-defining and everyday furnishings. Through advancements in manufacturing, a commitment to environmental stewardship, and the ability to meet extensive customization demands, fiber board secures its position not only as an alternative but often as the preferred solution for modern furniture makers. For buyers, architects, and designers seeking balance between elegance, value, and long-term performance, fiber board is poised to define the future of functional interiors.

(fiber board for furniture)

FAQS on fiber board for furniture

Q: What is fiber board for furniture used for?

A: Fiber board for furniture is commonly used in making cabinets, shelves, and other interior furnishings. It's popular due to its smooth surface and affordability. Many modern furniture pieces feature fiber board components.

Q: How is MDF fiber board different from other board types?

A: MDF fiber board is made from fine wood fibers and resin, offering a uniform and smooth finish. This makes it easy to paint and ideal for decorative furniture parts. It's denser and heavier than particle board but usually more affordable than solid wood.

Q: Is furniture board better than plywood for cabinets?

A: Furniture board is generally cheaper and has a smoother finish, while plywood is stronger and more moisture resistant. For heavy-use areas, plywood cabinets are preferred. Furniture board works well for less demanding applications.

Q: Can I paint or laminate fiber board for furniture?

A: Yes, fiber board for furniture can be painted or laminated easily due to its smooth surface. This makes it versatile for various design styles. Proper preparation ensures the best results.

Q: Is MDF fiber board environmentally friendly?

A: MDF fiber board is often made from recycled wood fibers, making it more eco-friendly than some alternatives. However, it may contain resins with formaldehyde, so look for low-emission products. Always check for certifications when choosing MDF.